The inherent flexibility of such equipment will allow them to take care of varying viscosities and accommodate distinctive container styles, empowering brands to efficiently offer varied formulations.

While in the dynamic realm of pharmaceutical manufacturing, liquid bottle filling machines stand as being the vanguards of effectiveness and precision. These cutting-edge automated methods have sparked a revolution while in the packaging of pharmaceutical liquids, propelling productivity although upholding uncompromising good quality Manage.

The Biosealer® TC is lightweight and may be operated on the desk or while hanging. Furthermore, the Biosealer® TC is portable and may be moved to wherever the sterile disconnection is desired.

Despite the worries connected to protecting aseptic problems with the production of these novel biologics, these products are highly at risk of microbial contamination as a result of handbook manipulations associated with their manufacturing.

This web site will not exist with your chosen language. Your preference was saved and you'll be notified at the time a web page may be seen with your language.

Biological drug goods, for example proteins or monoclonal antibodies, are predominately packaged into vials or prefilled syringes for intravenous or subcutaneous administration. Nevertheless, some biological drug merchandise must be administered by choice routes, such as pulmonary delivery in the shape of a mist using a nebulizer. In this type of scenario, using plastic ampuls as the first drug container presents quite a few pros above vials or syringes. Plastic ampuls are effortless, very simple to make use of, are unbreakable, and little one-welcoming.

When producing a sterile solution, individuals typically usually do not have an understanding of what’s necessary to manufacture the product. Does the molecule have to have aseptic filling, or can it be terminally sterilized? Is the appliance definitely a sterile system And exactly how do they uncover the correct CDMO to manufacture their merchandise safely and securely and proficiently?

Like traditional sterilization techniques, product or service filtration techniques have also remained largely unchanged for your past a number of a long time.

Automated and manual labeling; automatic, semi-automatic and manual inspection; UV code verification; variable print details; label placement; industrial labeling; second facts matrix verification

The Biosealer® TC offers a vast 20 mm seal For additional sturdy disconnection. Moreover, a slicing guideline embedded into your seal assures operators can make a clean up cut with scissors.

In this job interview, find out how Charles River employs the strength of microdialysis for drug growth as

A few distinctive processes within the drug creation operation were picked, that happen to be deemed vital and need more info ongoing adherence to superior manufacturing techniques. The goal is to handle the next concern: what methods/gatherings build an unacceptable risk to the standard of the product or service and/or the security with the individual for the duration of injectable item filling operations (1. entry and exit treatment to cleanroom, two.

The material of our Web page is often obtainable in English and partly in other languages. Pick out your chosen language and We're going to show you the click here content in that language, if accessible.

A “media fill” (occasionally called a “system simulation”) will be the effectiveness of the aseptic manufacturing technique employing a sterile microbiological expansion medium in place of the drug solution.

Jenna Von Oy Then & Now!

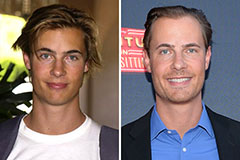

Jenna Von Oy Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!